Parabolic Mirrors

Parabolic reflectors are used to collect energy from a distant source (for example sound waves or incoming star light). Since the principles of reflection are reversible, parabolic reflectors can also be used to focus radiation from an isotropic source into a narrow beam. In optics, parabolic mirrors are used to gather light in reflecting telescopes and solar furnaces, and project a beam of light in flashlights, searchlights, stage spotlights, and car headlights. In radio, parabolic antennas are used to radiate a narrow beam of radio waves for point-to-point communications in satellite dishes and microwave relay stations, and to locate aircraft, ships, and vehicles in radar sets. In acoustics, parabolic microphones are used to record faraway sounds such as bird calls, in sports reporting, and to eavesdrop on private conversations in espionage and law enforcement.

Parabolic mirrors are typically designed as a segment of a larger parabola, manufactured from a metal substrate such as aluminum and coated in enhanced aluminum, silver or gold as standard. These mirrors focus light similar to a concave mirror with the significant exception being that the off-axis parabolic design redirects the incident light through 90%.

Custom mirrors may be manufactured in a range of substrates and alternative coatings as required by our customer's specifications including UV and IR coatings and materials and alternative reflection angles. We have parabolic reflectors for sale, if you want to buy parabolic mirror, please contact us. Because we have special parabolic mirror design service.

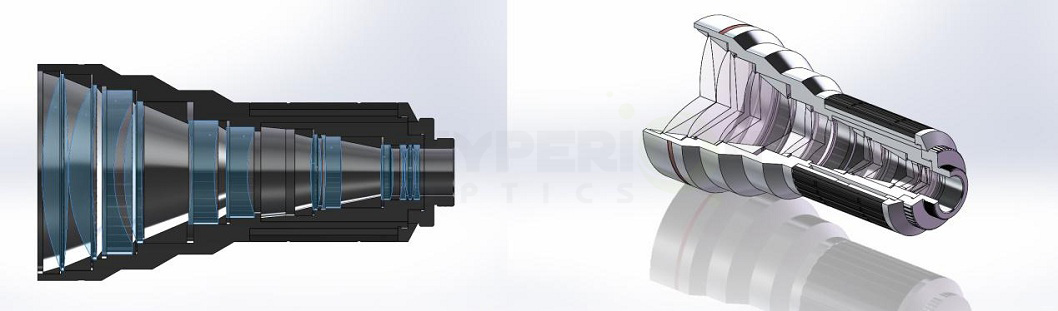

Hyperion Optics is a leading optics supplier of photonics products including optical components, lens systems and opto-mechanical assemblies in UV, Visible,NIR, SWIR applications. Our clients spanning across defense, security, bioengineering, pharmaceutical, institutional, industrial and research industries worldwide. We specialize in DFM (optical assembly manufacturing) input from rapid prototyping to volume production. Our comprehensive metrology coupled with our cost-effective philosophy help Hyperion customers obtain a competitive edge in the global market.

Compared to other Chinese vendors, Hyperion has the most experienced engineering team to provide technical backups and consultation for our customer with multi-languages skills, seamless communication is also an advantage. Free consultation for your optical system and preliminary design is also available now!

Labels: Parabolic mirrors