Anamorphic Lenses introduction, to buy from high quality manufacturer

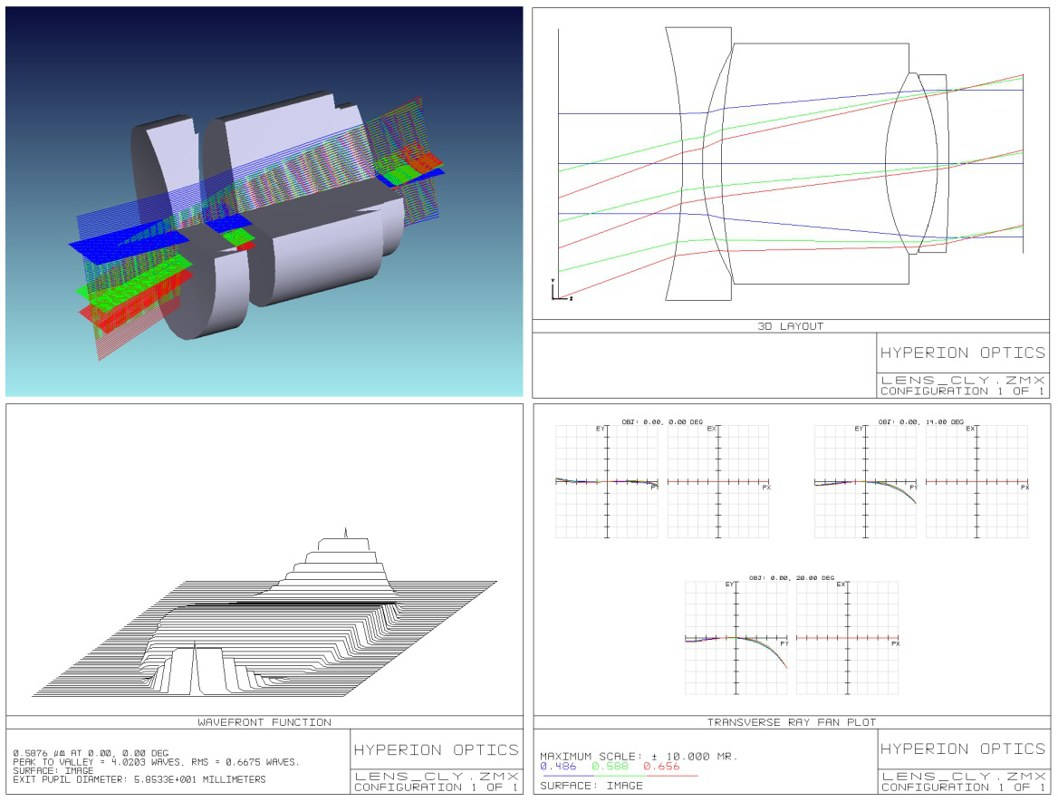

Hyperion Optics specialized in custom anamorphic lenses design and production. We have been customizing unique applications such as projection and anamorphic photography. Generally speaking, these lenses are special tools that affect the aspect ratios and get projected onto the camera sensor.

Compared to spherical lenses, which are common and project images onto the sensor without causing aspect ratio change, anamorphic lenses compressing along the longer dimension, which require subsequent stretching, in post-production or at the projector to be properly displayed.

With our high quality achromatic cylindrical lenses production capability, we are able to meet the most demanding anamorphic design performance, please refer to our cylindrical lens fabrication capability. To note, in some cases, custom design achromatic cylindrical lenses are extremely thick in CT, we are able to cement singlet parts on real time alignment device to avoid thickness unavailability of certain materials.

Here is a great sample that how anamorphic projection lenses can contribute:

We begin with a cinemascope screen. Here we’re displaying a 2.35 or 2.40 film, Note the black bars top and bottom.

The first step is to electronically stretch the image vertically. This is either called ‘vertical stretch’ or ‘zoom’ or ‘anamorphic mode’. This feature can be found many projectors and Blu Ray players. We have taken the active illuminated pixels in the black bars and scaled them back into the image. This process increases the overall on screen luminance or brightness. Once vertically stretched, everything on screen looks tall and skinny- compare the image below with the image above.

The final step is the optical expansion of the vertically stretched image to restore the geometry and to fill the entire cinemascope screen with active image. The result here is an image that is 78% larger than the original- Now compare top and bottom images.

Highlights of Hyperion Optics’ anamorphic design

- Expected aspect ratio control

- Sharp image quality, MTF can be tested according to requirement

- Excellent achromatic feature

- Design fit for 2.35, 2.39 and 2.4 aspect ratio

- Theatrical cinema projection design available

Structural Design: Introduction to Connection Form of Optical Components

One:Connection request

In order to ensure that optical instruments are false, some require the quality of light, and the connection between optical components and mechanical is as follows1) The relative position between the optical parts and the mechanical parts should be accurate. A lens optical system should be used to ensure the accurate distance between lenses and lenses. And as a component made of non-circular optical systems, optical components should be asked of a working face with mechanical components on a point, line, or face the relative position between the right.

2)It is easy to assemble, adjust, and ensure the strong, stable and reliable connection.

3)It will not lead to the distortion of optical components or the production of large internal stresses, which will not alter the performance of optical components.

4)The SS ensures that when the temperature of the environment changes, the internal stresses resulting from the connection and optical components are minimized, which will not affect the performance of the optical components.

5)Cleaning of optical components do not affect the light road and the area of the light.

Two:The connection of optical components

Round optical components include lenses, splitters, filters, mirrors and protective glass. Common connections for rolling edge, compression ring, elastic press, electroplating, cementing and so on.1.The connection of rolling edge

The connection of rolling edge is unbroken and the connection structure is shown in figure 13.35. Its structure is simple, compact, light area of effect is very small, but the connection may occur a phenomenon that the tilt and pressure are uneven, aberration goes bad and affect the imaging quality, for larger diameter circular optical components is more serious. As a result, this type of connection structure is usually used for less demanding, smaller sizes.

2.The connection of compression ring

The compression ring connection is detachable. This connection is convenient for assembly and adjustment, if necessary, add elastic space ring, can make the pressure force is uniformly distributed on the optical components, and can reduce the influence of temperature on the compression force. This connection is suitable for the larger, more demanding round optical components.

3. The connection of elastic press

The elastic press connection is removable. The spring card ring is usually only used for optical components that are not high in alignment and solidity. Such as protecting glass and filter glass, the elastic press is used to press the larger optical components.

4. The connection of electroplating, which belongs to the unbroken connection, is used electroplating method to plate copper in the end of the frame, blocking the optical components. The optical components in the electroplating connection are not compressive, only for the connection of small diameter optical components.

5. The connection of cementing

When the copper plated connection is converted to the bonding agent, it becomes the glue joint. There is also no compaction on the optical components.

Three:The connection of non-circular optical components

Non-circular optical components include prisms, reflectors, glass and protective glass. The structural design requirements for non-circular optical components are essentially the same as the circular optical components.Four:The basic principle of the connecting structure in the instrument:

Hyperion Optics introduces the basic principle of connecting structure in the instrument:1)To ensure the strength and accuracy of the instrument

2)To ensure the reliability of the components under use;

3)In order to simplify the structure, it should be possible to use an undetachable connection

4)Components that need to be adjusted, repaired and replaced should be detachable

5)When there is a number of connections in the part, it is usually necessary to have an undetachable connection for the components or the internal components that are first assembled: the components or the external components that are attached are disassembled

6)Ensure that the components and connections of first and later assembly will not affect each other.

7)Ensure that the components are not deformed or are the least deformed

8) Fewer specifications are better to use connections, don’t use the fine thread connections as possible.

Labels: anamorphic lenses, Hyperion Optics, lens, lens assembly, optical components

0 Comments:

Post a Comment

Subscribe to Post Comments [Atom]

<< Home